Submit

Submit feedback

Does The Material of The 6061-T6 Aluminum Wheel Meet The Modification Standards?

2026-01-04

Material Suitability as the Core Question in Wheel Modification

The practice of modifying automotive wheels, whether for aesthetic enhancement, performance gains, or functional necessity, introduces a complex set of engineering and safety considerations. Central to this endeavor is the fundamental question of material suitability. In the context of common aftermarket alterations—such as machining for a wider stance, drilling for alternative bolt patterns, or reshaping for custom designs—the inherent properties of the wheel's base material become critical. The widespread use of 6061-T6 aluminum alloy in OEM (Original Equipment Manufacturer) and aftermarket wheels makes it a frequent subject of such inquiries. Determining whether this material "meets modification standards" is not a matter of simple affirmation or negation, but rather a nuanced examination of the alloy's characteristics, the nature of the intended modification, and the governing principles of mechanical integrity.

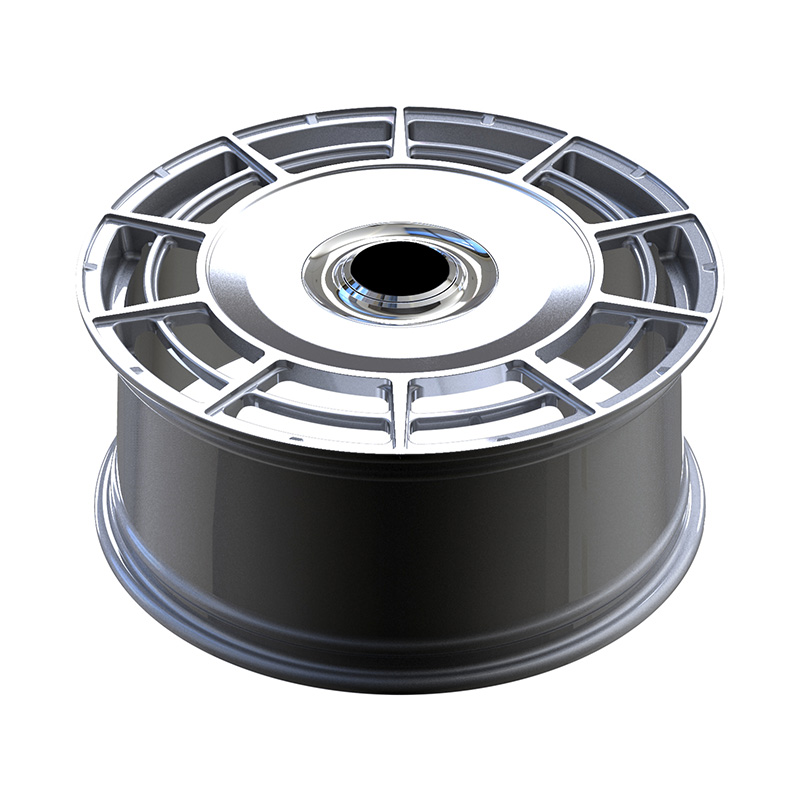

Properties and Appeal of 6061-T6 Aluminum in Wheel Manufacturing

6061-T6 aluminum is a precipitation-hardened alloy, with magnesium and silicon as its primary alloying elements. The "T6" designation indicates a specific thermal treatment: solution heat treatment followed by artificial aging. This process yields a material with a balanced profile of properties: moderate-to-high strength, good corrosion resistance, machinability, and favorable weight characteristics compared to steel. These qualities make it a logical and effective choice for mass-produced wheels, offering a sound compromise between performance, durability, and manufacturability. Its machinability, in particular, is often cited by those wishing to modify wheels, as it allows for relatively clean cutting and drilling operations.

Structural Consequences of Modifying a Safety-Critical Component

However, the very act of modification engages in a delicate dialogue with the material's engineered state. A wheel is a safety-critical component, bearing dynamic loads that combine vertical weight forces, lateral cornering stresses, and impact shocks from road imperfections. Its structural design, as validated by the manufacturer, assumes a specific geometry and material condition. When material is removed—through machining, drilling, or welding—several consequential effects are introduced. The local cross-sectional area is reduced, potentially creating new stress concentrations in areas not originally designed to accommodate them. Second, and more subtly, the heat input from machining or welding can alter the localized metallurgical structure of the 6061-T6 alloy.

Thermal Effects, Metallurgical Degradation, and Load Redistribution

The T6 temper is a metastable condition achieved through precise thermal control. Introducing concentrated heat, as in welding or even aggressive machining without proper cooling, can precipitate over-aging in the heat-affected zone (HAZ). This can significantly reduce the yield and tensile strength in that localized area, effectively creating a weak point in a highly stressed component. A wheel that appears visually sound may harbor a zone of compromised material properties invisible to the eye. Furthermore, modifications that alter the wheel's offset or width change the lever arms through which forces are transmitted from the tire to the hub, placing stresses on different areas of the wheel than originally intended.

Defining“Modification Standards" Through Engineering Practice and Risk Control

Therefore, the concept of "modification standards" must be carefully defined. There are no universal, publicly codified standards that explicitly govern the aftermarket modification of a finished aluminum wheel in the same way that there are standards for their initial manufacture (such as those from SAE International or national transportation authorities). Instead, the standard is one of engineering practice and consequential safety responsibility. From this perspective, the suitability of 6061-T6 hinges entirely on the execution of the modification.

A professional, knowledgeable approach that treats the 6061-T6 Aluminum Wheel as a structural element rather than a mere aesthetic object is necessary. This involves several key considerations. The design intent of any modification should be analyzed, ideally with engineering oversight, to understand load paths and potential new stress risers. Machining must be performed with sharp tools and adequate cooling to minimize heat buildup and plastic deformation. Processes like welding should be followed by a controlled re-heat treatment of the entire wheel to restore the T6 temper uniformly, a procedure that is complex, costly, and often impractical outside specialized facilities. Critically, any modified wheel must undergo rigorous non-destructive testing (such as dye penetrant or X-ray inspection) to check for cracks or defects, and ideally, destructive testing (like radial fatigue and impact tests) on sample units to validate the modified design.

recommend products

-

Zhenlun Multi Spokes Split Monoblock Forged Wheels Bronze With Silver Lip Edge

-

Zhenlun Matt Black With Red Lip Monoblock Forged Wheels

-

Zhenlun Gloss Black Monoblock Forged Wheels Gloss Black For Sports Car

-

Zhenlun Monoblock Forged Wheels Lightgrey With Machined Face

-

Zhenlun Monoblock Forged Wheels Gloss Black Dense Multi Spoke

0

0