-

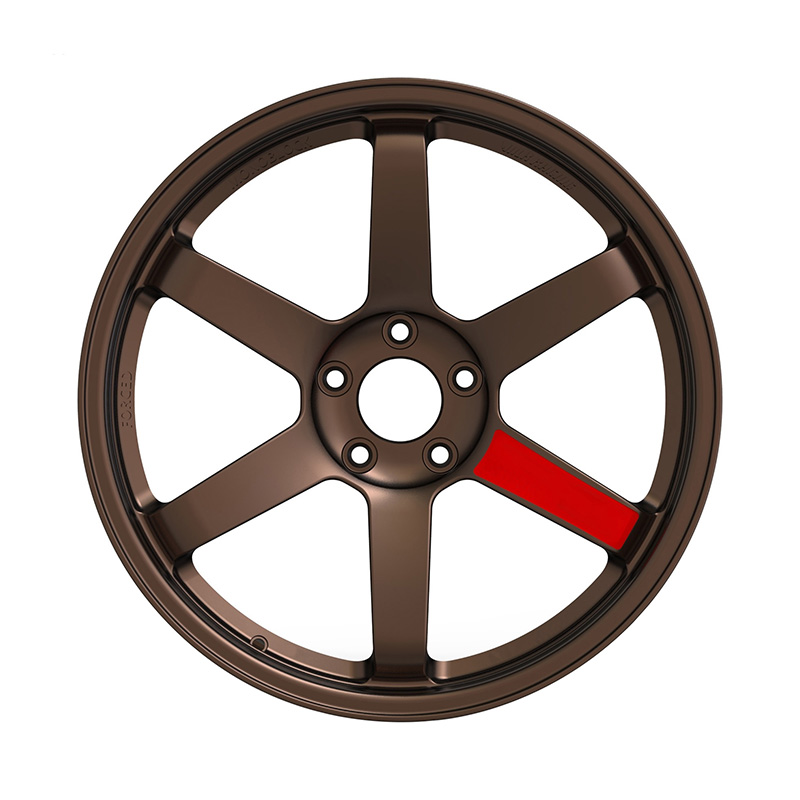

The color of this 2-pieces forged wheel is brush silver. It has multi split spokes. Enhance contrast at the same time to make the design highlight the sense of layer, enhance the wheel visual expansion tension. A ring of rivets design to make it look more delicate. The delicate of the two-piece wheels retain the strength and reliability. It's ideal for sports car and MPV.

Compared to the monoblock wheel, the double-piece wheel will be heavier,it can be thought of as a wheel made up of two wheels. But for some car owner who like retro styles, for the needs of the deep dish or deep lip wheel of the car, the two-piece can better meet their needs. We can adjust and custom structure of spokes, color of wheels, and put your own letters on the wheel as your needs.

Furthermore, the material of our 2-piece forged wheel also used high quality forging blanks which offer higher strength, better heat dissipation, better ductility and light weight than cast and flow forming wheels, so it not only offer a more refined look, but also improve performance and security for you. -

Material: 6061t6-aluminum alloy

Color: Brush silver

ET: Customized

PCD: Customized

Style: 2-Pieces Forged Wheels

Finish: Full coating

Size: 18-24inches -

Submit

Submit feedback

-

Feb 06,20266061-T6 aluminum wheels are widely used in modified vehicles because they offer ...Read More

-

Jan 28,2026The Role of Aluminum Alloys in Forged Wheels Aluminum alloys are the primary mat...Read More

-

Jan 23,2026Modifying a vehicle with aluminum alloy forged rims involves a series of technic...Read More

Industry Knowledge Extension

What are the special features of 2-Piece Multi Spoke Forged Rims?

2-piece multi-spoke forged rims have grown in popularity among automotive enthusiasts and professionals due to their strength, lightweight properties, and customization options. What exactly makes these rims stand out?

|

Feature |

Description |

|

Forged Construction |

The rim is made from a single piece of metal, shaped under high pressure. This process increases strength, making the rim more resistant to cracks and deformations compared to cast rims. |

|

Multi-Spoke Design |

The rim features multiple spokes, often designed to enhance both performance and aesthetics. This design improves weight distribution and adds visual appeal. |

|

Customizability |

2-piece rims are often customizable, allowing customers to choose finishes, colors, and spoke patterns to suit their personal or brand preferences. |

|

Lightweight |

Due to the forging process and the multi-spoke design, these rims are generally lighter than cast alternatives, contributing to better vehicle handling and performance. |

|

Durability |

The forged nature of the rims, combined with the multi-spoke design, enhances overall durability. These rims can withstand high forces, which is particularly important in high-performance vehicles. |

These features combine to make 2-piece multi-spoke forged rims not just a functional choice but a stylish one as well, offering both performance and design flexibility.

Are forged aluminum wheels sturdy? Can you feel the difference?

Forged aluminum wheels have become a preferred choice for those seeking both lightweight and durable options for their vehicles. But how sturdy are they, and can you truly feel a difference when compared to other types of wheels? Here’s a detailed look:

What makes forged aluminum wheels sturdy?

Forged aluminum wheels are made by subjecting aluminum to high pressure and heat, shaping the metal into the desired form. This process results in a tighter grain structure, which improves the overall strength of the wheel. Unlike cast wheels, which are poured into molds, forged wheels are denser, making them more resistant to cracking and damage.

How does the material affect performance?

Aluminum, as a lightweight material, offers significant performance benefits. It reduces the overall weight of the vehicle, allowing for quicker acceleration, improved handling, and better fuel efficiency. The forged process further enhances the structural integrity, meaning these wheels can handle higher loads and pressures without deforming.

Can you feel the difference in handling?

You can feel the difference. Forged aluminum wheels provide superior performance, especially in high-performance or racing vehicles. They allow for better response during cornering and braking. The reduced weight also minimizes the rotational mass, which improves the vehicle's handling. In daily driving, you may notice a smoother ride and faster acceleration due to the lighter weight.

How do they compare to cast aluminum wheels?

While cast aluminum wheels are cheaper, they are not as strong or lightweight as forged wheels. Cast wheels are more likely to crack under stress, whereas forged wheels tend to have higher tensile strength. In terms of durability, forged wheels last longer and maintain their structural integrity for a longer period of time.

Will brushed forged wheels crack or deform?

Brushed forged wheels, known for their sleek, matte finish, are a popular choice for those looking to add a touch of style to their vehicle. However, many people wonder about their durability, particularly whether they are prone to cracking or deformation. Let’s explore the factors that affect the longevity of these wheels.

What causes cracking or deformation in wheels?

The primary cause of cracks or deformation in wheels is excessive force or impact. For instance, hitting a curb or pothole at high speeds can cause damage to any type of wheel, including brushed forged wheels. However, the high strength of forged wheels generally makes them more resistant to such impacts compared to cast wheels.

Are brushed finishes more prone to damage?

A brushed finish on forged wheels is mostly an aesthetic choice and does not affect the underlying strength of the wheel. However, the finish can show scratches or scuffs more readily compared to polished or matte finishes. Over time, repeated exposure to road debris or rough conditions can wear down the finish, but the structural integrity of the wheel itself is unlikely to be affected unless subjected to significant impact.

How durable are forged wheels overall?

Forged wheels, including those with brushed finishes, are designed to handle significant stress without cracking or deforming. The forging process results in a denser, stronger wheel, which is less likely to bend under pressure. However, extreme conditions, such as high-speed impacts or prolonged exposure to corrosive elements, can still cause damage. Regular maintenance, such as cleaning and inspecting the wheels for cracks, can help prolong their lifespan.

What about the performance impact?

Even if a brushed forged wheel sustains minor cosmetic damage, the overall performance will not necessarily be affected. The integrity of the wheel is crucial for maintaining performance, and because brushed forged wheels are highly durable, they are unlikely to lose their strength unless seriously damaged. However, any visible damage should be repaired promptly to prevent further issues.

0

0