-

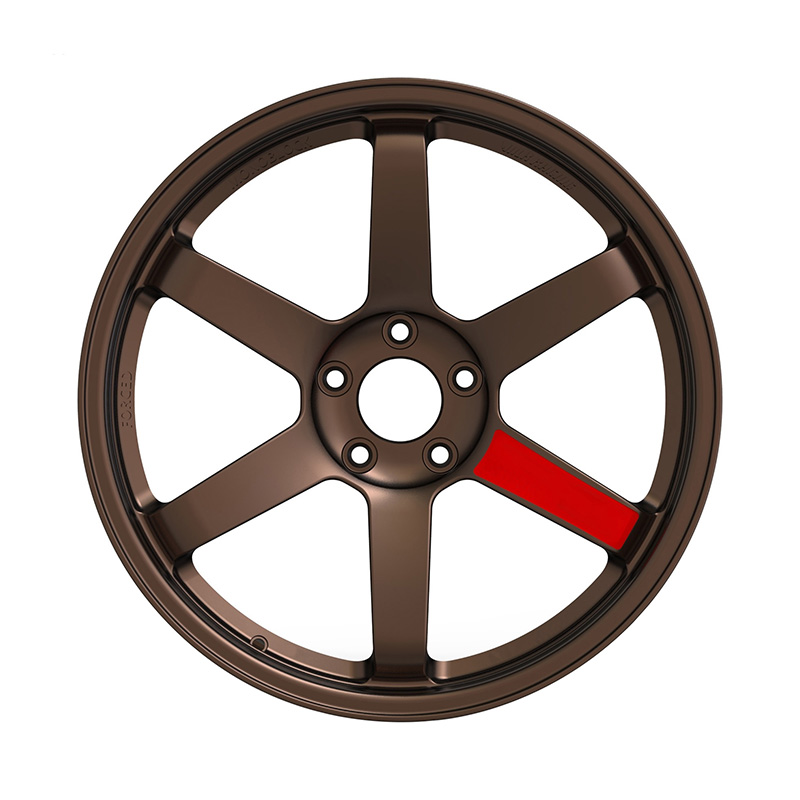

Introducing the Zhenlun Concave Design Gloss Black Multi-Spoke Monoblock Forged Wheels. These high-performance wheels feature a sleek gloss black finish and a distinctive multi-spoke design. Crafted from a single piece of forged aluminum, they offer exceptional strength and lightweight performance. The concave profile not only enhances the visual appeal but also improves aerodynamics. Ideal for high-end sports cars and luxury vehicles, these wheels combine style with nice engineering for an unmatched driving experience.

Feature:

The monoblock Forged Wheels are constituted by a multi-spoke design. On the spokes there is a beveled design, gloss black and silver interlace, when the car is in the process of driving will be very particular. It provides a more mystery feeling, this design also makes the wheels look less monotonous.

Compared with cast wheel flow forming wheel forged wheel has higher strength and ductility with relatively less weight due to their tighter internal molecular structure that offers better performance and safety during driving.

Furthermore, we can custom these forged wheels exclusively in different colors of passenger cars without spacers, center ring and flange, and we can also change structures and put your logo on the wheel according to your needs by experienced designer team support. -

Material: 6061t6-aluminum alloy

Color: Gloss black

ET: Customized

PCD: Customized

Style: Monoblock Wheels

Finish: Machined face/ polishing face

Size: 16-24inches -

Submit

Submit feedback

-

Feb 20,2026The Significance of Monoblock Forged Wheels A monoblock forged wheel is not simp...Read More

-

Feb 13,2026Custom forged wheels exist because vehicle modification demands solutions that a...Read More

-

Feb 06,20266061-T6 aluminum wheels are widely used in modified vehicles because they offer ...Read More

Industry Knowledge Extension

A Guide to Contemporary Wheel Design: Form, Finish, and Fabrication

The selection of wheels for a vehicle involves a series of interconnected decisions, balancing visual intent with mechanical requirements and manufacturing methods. This examination explores three specific areas: the appeal and considerations of deep concave designs, the distinctive characteristics of a popular finish, and the technical processes behind a common wheel construction.

What defines a "deep concave" design, and how is it achieved?

A deep concave design refers to a wheel where the spokes exhibit a pronounced inward curvature from the outer rim toward the hub, creating a recessed, three-dimensional appearance. This effect is primarily a function of wheel offset and spoke geometry. It is achieved through careful engineering of the forging mold and is often more feasible on wheels with higher negative offsets, where the mounting pad is positioned closer to the outer lip of the wheel, allowing the spokes to sweep inward. Monoblock forged construction is frequently used for such designs, as the forging process can accommodate significant concavity while maintaining material strength.

Are there functional trade-offs with a deep concave design?

While a well-engineered concave wheel maintains structural integrity, certain trade-offs exist. The design can sometimes add slight weight compared to a shallower, straighter-spoke design of the same size due to the need for more material in the sculpted spokes. The primary considerations, however, relate to fitment. A deeply concave wheel requires specific clearances to avoid contact with brake components, suspension parts, and the inner wheel well. Successful installation often depends on precise measurements of brake caliper size, suspension geometry, and fender modification.

What are the notable features of Gloss Black Monoblock Wheels?

Gloss black monoblock wheels present a specific aesthetic and practical profile that distinguishes them from other options. Their features arise from both the finish and the construction method.

The most apparent feature is the visual impact. A high-gloss black finish creates a uniform, dark surface that emphasizes the wheel's form and spoke design. It tends to minimize visual mass, making the wheel appear simpler and often lending the vehicle a modern, assertive presence. This finish can provide a contrast with the vehicle's body color or contribute to a cohesive, monochromatic theme.

From a practical standpoint, the monoblock forged construction underlying the finish offers benefits. The one-piece forging yields a wheel with a good strength-to-weight ratio and consistent material density. The gloss black finish itself, typically involving a multi-stage process of primer, base color, and clear coat, offers a degree of protection against corrosion and minor abrasions. However, a notable characteristic of this finish is its maintenance requirement. The glossy surface readily shows brake dust, water spots, and fine scratches, necessitating regular and careful cleaning to preserve its intended appearance.

What manufacturing processes are involved in Multi Spoke Monoblock Forged Wheels?

The creation of a multi-spoke monoblock forged wheel involves a sequenced transformation from raw material to finished product. The following table outlines the key stages in this manufacturing workflow.

|

Manufacturing Process Stage |

Description and Key Actions |

|

1. Billet Preparation |

A cylindrical billet of high-grade aluminum alloy (e.g., 6061-T6) is cut to a specific weight and mass suitable for the final wheel dimensions. |

|

2. Pre-forging / Pre-forming |

The billet is heated and subjected to initial pressing. This step begins to shape the material into a rough, puck-like form, consolidating the metal grain structure. |

|

3. Hot Forging |

The pre-formed puck is heated and placed into a large, hydraulic forging press under extremely high pressure (several thousand tons). It is stamped into a near-net-shape "forging blank" that closely resembles the final wheel profile, including the basic spoke structure. |

|

4. Heat Treatment |

The forged blank undergoes a controlled sequence of solution heat treatment and artificial aging (T6 temper). This process enhances the aluminum's mechanical properties, optimizing its strength and durability. |

|

5. CNC Machining |

The heat-treated blank is mounted on a computer numerical control (CNC) milling machine. Using digital blueprints, the machine precisely cuts all final details: spoke contours, bolt holes, hub bore, mounting pad, and rim profiles. This step defines the precise multi-spoke design. |

|

6. Finishing |

The machined wheel undergoes surface preparation, which may involve polishing, grinding, or shot blasting. It is then cleaned and prepared for painting, powder coating, or other finishing treatments before final quality inspection. |

0

0